Guangdong Jiema Energy Saving Technology Co.,Ltd

Shell Exchanger,1 Shell 2 Pass Heat Exchanger,In Shell and Tube Surface Condenser

Guangdong Jiema Energy Saving Technology Co.,Ltd

Shell Exchanger,1 Shell 2 Pass Heat Exchanger,In Shell and Tube Surface Condenser

| Unit Price: | USD 300 / Piece/Pieces |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,Express Delivery,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Piece/Pieces |

Brand: Jiema

Material: Carbon steel, Stainless steel

Usage: Cooling, Heating

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Land,Ocean,Air,Express

Place of Origin: Guangzhou

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: T/T,L/C

Incoterm: FOB,Express Delivery,CFR,CIF,EXW,DDU

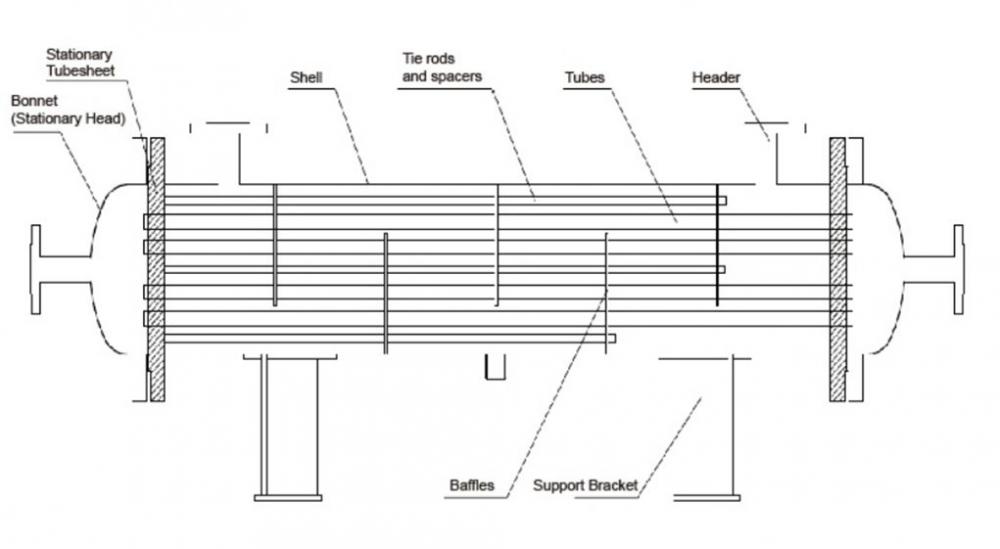

Head plates, shell, tube bundles, mounting Flange and more make a Jiema Carbon Steel Shell Exchanger for Beer Wort Cooling complete. For one liquid medium, we guide it through the tubes that are connected with the head plates, with several number of passes available in accord with different working conditions. For another, it makes its way into the shell and is uniformly distributed over the outer tube.

Regarding the technical requirements from our customers, our 1 Shell 2 Pass Heat Exchanger, or In Shell and Tube Surface Condenser, then sets a few baffles in a bid to increase turbulence and promote more heat exchange. Aside from that, the heat transfer master himself, tube bundles, ranges from brass tube, copper-Finned Tube to steel tube with an attempt to realize heating and cooling of various working fluids.

(e.g. Water-Oil Heat Transfer)

1. Check all the attachments, digital instruments, and connections.

2. Take off the plug screw at the oil inlet, and open the inlet valve slowly. While the oil overflows, close the valve immediately.

3. Take off the plug screw at the water inlet, and again open the inlet valve of cooling water slowly(outlet valve of the water side stays closed). Shut the inlet valve once the water spills. Now let the two exchange heat as they stay still and gradually reach temperature equation.

4. As the water temperature reaches 5-10℃,open the cooling water outlet valve, and gradually the inlet valve as well. At this time, it is necessary to leave the valve of oil outlet open, and gently open its inlet valves too. In this way, both fluids are eventually flowing. The last step is to slightly adjust the water quantity of flow so as to keep the oil temperature well within our expectation.

5. Do not attempt to quickly open the inlet valve, because the sudden supply of cooling water would create an “over-cooling surface” that has poor thermal conductivity. After that, even though a great amount of water flows into the exchanger, the cooling result isn’t satisfying at all.

6. Pressure of the oil side shall be higher that that of the water side.

7. If there is electrochemical corrosion at the water side, zinc bar could be installed at the required place.

Expert in Waste Heat Recovery Equipment

Expert in Waste Heat Recovery Equipment

Top R&D Center for Energy Saving Technology

Leading Manufacturer with Customized Products and Excellent Service

1. What are the application scenarios for Carbon Steel Shell Exchanger?

Floating Head Heat Exchanger, say Carbon Steel Shell Exchanger or 1 Shell 2 Pass Heat Exchanger is to be applied to situation where there will be heavy scale and easy corrosion at the tube side. Besides, it can do perfectly well under restrict requirements for high temperature and pressure.

2. Why Floating Head Heat Exchanger will cost me so much money?

High expense of Floating Head Heat Exchanger has to do with its complex fabrication. Apart from other necessary components such as shell and tube, our Floating Head Heat Exchanger, like In Shell and Tube Surface Condenser, consists of an additional floating head that would not be affected by thermal stress and have a long service time during the operation.

Product Categories : Shell And Tube Heat Exchanger > Floating Head Heat Exchanger