Guangdong Jiema Energy Saving Technology Co.,Ltd

Tube Sheet Heat Exchanger,Shell and Tube Chiller,S&T Heat Exchanger

Guangdong Jiema Energy Saving Technology Co.,Ltd

Tube Sheet Heat Exchanger,Shell and Tube Chiller,S&T Heat Exchanger

| Unit Price: | USD 300 / Piece/Pieces |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,Express Delivery,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Piece/Pieces |

Brand: Jiema

Material: Carbon steel, Stainless steel

Usage: Cooling, Heating

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Land,Ocean,Air,Express

Place of Origin: Guangzhou

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: T/T,L/C

Incoterm: FOB,Express Delivery,CFR,CIF,EXW,DDU

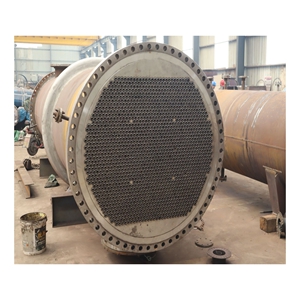

Tube Sheet Heat Exchanger for Slop Oil Cooling or Shell and Tube Chiller, from its on-site photographs, has a distinct mechanics from other Shell and Tube Heat Exchangers such as Fixed Tube Heat Exchanger and U Tube Heat Exchanger. To illustrate, its rear head cover is fixed and cannot be removed. At the same time, the floating head cover at the front, is free to move inside the shell, namely, to move up and down.

With that being said, thermal expansion of the S&T Heat Exchanger is of no harm to the equipment. Beyond that, tube bundles of our Tube Sheet Heat Exchanger allows thorough cleansing after being removed from the shell. However, there is no such thing as a free lunch. The multifunctional characteristics of Shell and Tube Chiller comes with complicated fabrication and high price. It is mostly applied in fields where high temperature difference and heavy fouling are the main concerns.

1. Hydrostatic test pressure would be 1.5 times higher than the operating pressure with the duration of 10 minutes; (Steam:+0.3MPa;Hot water:+0.4MPa)

2. Space shall be left for future removal of the tube bundles; estimated distance between the floating head and the wall/roof of the room should be no less than the total length of the equipment;

3. Relevant valves and digital instruments shall be installed at a height that is best suitable for operation and observation;

4. Vertical clearance between the highest location of upper attachment(mostly safety valve) and the floor shall meet the installation requirements and not less than 0.2m.

Tube Sheet Heat Exchanger, also Shell and Tube Chiller, is big hit among manufacturers from the chemical engineering industry, petroleum industry, energy industry and others. It helps our customers to realize heat exchanging under high temperature and pressure requirements with easy assembly and cleansing.

With rich practical experience in various industrial and civil applications, our technical professionals can provide our customers with accurate and reliable solutions, and then select a corresponding heat exchanger equipment according to the real requirements of customers.

With rich practical experience in various industrial and civil applications, our technical professionals can provide our customers with accurate and reliable solutions, and then select a corresponding heat exchanger equipment according to the real requirements of customers.

1. Is Tube Sheet Heat Exchanger removable?

Yes, it is. Our Tube Sheet Heat Exchanger can be removed from the floating head and be cleaned.

2. What is baffle in Shell and Tube Chiller?

Baffle is a flat plate installed inside the shell at a vertical angle with an attempt to increase the velocity of the shell side fluid and its number of passes. As a result, the heat transfer area multiplies by a great amount and so as the heat exchange efficiency.

Product Categories : Shell And Tube Heat Exchanger > Floating Head Heat Exchanger