Guangdong Jiema Energy Saving Technology Co.,Ltd

Spiral Type Plate Heat Exchanger,Spiral Type Plate Preheater,Spiral Plate Heater Cooler

Guangdong Jiema Energy Saving Technology Co.,Ltd

Spiral Type Plate Heat Exchanger,Spiral Type Plate Preheater,Spiral Plate Heater Cooler

| Unit Price: | USD 1000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

Brand: JIEMA

Test Pressure: 1 MPa

Design Pressure: 1 MPa

Packaging: plywood

Productivity: 100000 sets

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou,China

Supply Ability: 100000 sets

Certificate: ISO/CE

Port: Guangzhou

Payment Type: L/C,T/T,D/P,D/A

Incoterm: FOB,CFR,CIF,EXW

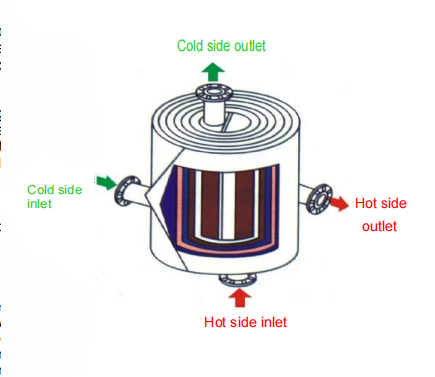

The structure of the non-detachable Spiral Plate Heat Exchanger is simple, and both ends of the spiral channel are welded. Spiral plate heat exchangers are widely used. For exemple, spiral plate heat exchangers have been mostly used to replace shell-and-tube heat exchangers in the shift heat exchangers of small and medium-sized ammonia plants and the lower part of the synthesis tower. For the electrolyte heater and concentrated lye cooler in the caustic soda plant, the equipment cost of the Spiral plate heat exchanger is only 1/3 of that of the Shell And Tube Heat Exchanger. In addition, this heat exchanger has good results in column top condensation, quenching oil cooling, oleum cooling and fatty acid cooling.

1. High heat transfer capacity: The nozzle on the shell is a tangential structure, the local resistance is small, the curvature of the spiral channel is uniform, the liquid flow in the equipment does not have a large reversal, and the total resistance is small, so the design flow rate can be improved to make it more efficient.

2. The end face of the spiral channel is welded and sealed, with good sealing performance and reliable structure.

3. Mechanical cleaning cannot be performed. The spiral plate heat exchanger is not easy to block compared with the general tubular heat exchanger, especially the suspended particles such as sediment and small shells are not easy to deposit in the spiral channel.

4. Because the space between the fixed column supports the channel in the spiral channel, no fibrous impurities (cotton yarn, straw sticks, leaves, etc.) should enter the heat exchangers.

Product Categories : Spiral Plate Heat Exchanger