![]() June 05, 2023

June 05, 2023

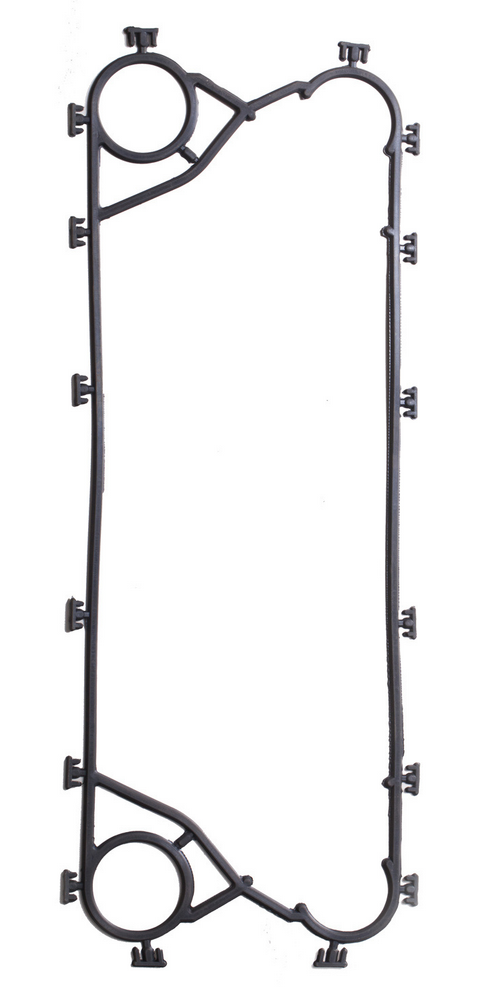

It is the inspection and testing of reuse performance. Check the wall thickness of heat exchangers and pipes in the case of suspected corrosion. The second is to remove aging seals. According to different dirt, use acid and alkali for chemical cleaning. The surface of the cleaned parts will not be affected by chemical media. Corrosion damage: second, after chemical cleaning, use a high-pressure blowing device to thoroughly remove the chemical medium remaining on the surface of the plate heat exchanger; fourth, each heat exchanger plate is coated with a fluorescent test agent, and under the irradiation of ultraviolet light Check for small cracks and corrosion holes, and clean again. In addition, it is also necessary to focus on checking the condition of the sealing groove, and repairing if necessary: Fifth, for the adhesive gasket, the residual substances will be completely removed, and the rebonded adhesive will be used to rebond, and the reassembled heat exchanger sheet group Clamp it in a special fixture to cure the adhesive, and heat it in a holding furnace to achieve the best bonding effect.

The above is the Maintenance of rubber gaskets in plate heat exchangers we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry