Plate heat exchangers can be used as waste water heat exchangers for applications where heat is recovered or released from contaminated liquids (usually water). Typical applications are as follows:

1. Untreated wastewater from sewers

Wastewater flowing into sewers has a huge thermal potential. This potential can be used to heat water for buildings if it is treated with a Preppler heat exchange system. The solution should maintain a certain flow rate, generally 0.8-1.2m/s. Its purpose is to increase the degree of turbulence of the solution.

water supply. The heat extracted from the wastewater with this treatment method is "pumped" to a higher temperature level. Since the sewers are always located close to the building, short passages are guaranteed, and the heat supplier and heat consumer are practically neighbors. The reverse is also true – for cooling purposes, heat is removed from the building and passed through a heat exchanger system that leads to the sewer.

2. Water from sewage treatment plants

The Preppler heat exchange system is an economical and environmentally friendly energy treatment system, also suitable for operators of sewage treatment plants. Because it is not only untreated wastewater, but also wastewater from wastewater treatment plants, which provide a huge source of heat. The ever-increasing volume of water and cooling water opens up new avenues for increasing the energy efficiency of the entire wastewater treatment plant. The sludge dryer not only uses solar radiation as drying energy, but also uses the thermal potential of the effluent from the sewage treatment plant. Process chain Sewage treatment plant waste water - heat exchanger - heat pump provides thermal energy for the high-performance floor heating of the sewage sludge dryer and ensures that the sludge is dry all year round.

3. Sludge dehydration Digested sludge and filtrate

High temperature = high energy recovery. This simple formula applies if the Preppler wastewater heat exchanger is fed by digester sludge or filtrate from a sludge dewatering system in a sewage treatment plant.

The temperature in the digester is about 36°C, but this high heat has never been used before. Due to its special design and automatic cleaning, the waste water heat exchanger is able to guarantee a continuous high heat transfer with these media.

The recovered energy can be directly used to preheat the raw sludge on site. From the point of view of saving energy, the hydrostatic primary pressure of the biogas digester does not require additional feed pumps.

4. Industrial wastewater

Like the municipal sector, industrial businesses also lose significant amounts of energy in their wastewater flows. Especially in physical and chemical processes, very high temperatures can be reached.

Many companies now work 24 hours a day, so that they can provide continuous traffic. In most applications, the recovered energy can be directly introduced into the industrial process, resulting in shorter production line lengths. The heat extracted from the wastewater has positive side effects to meet discharge requirements.

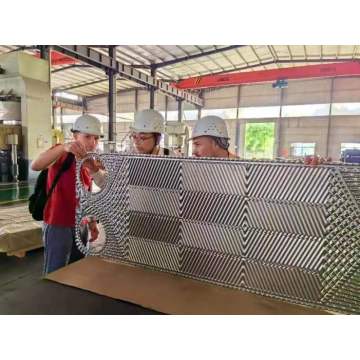

![]() August 10, 2023

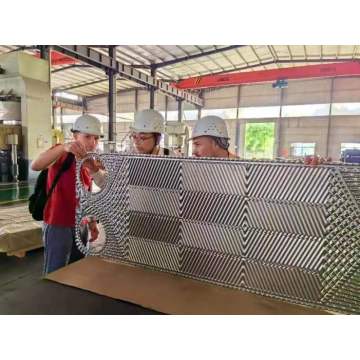

August 10, 2023