Guangdong Jiema Energy Saving Technology Co.,Ltd

Spiral Heat Exchanger,Spiral Plate Exchanger,Spiral Exchanger

Guangdong Jiema Energy Saving Technology Co.,Ltd

Spiral Heat Exchanger,Spiral Plate Exchanger,Spiral Exchanger

| Unit Price: | USD 300 / Piece/Pieces |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,Express Delivery |

| Min. Order: | 1 Piece/Pieces |

Brand: Jiema

Material: Carbon steel, Stainless steel

Usage: Cooling, Heating

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou, China

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,DDU,Express Delivery

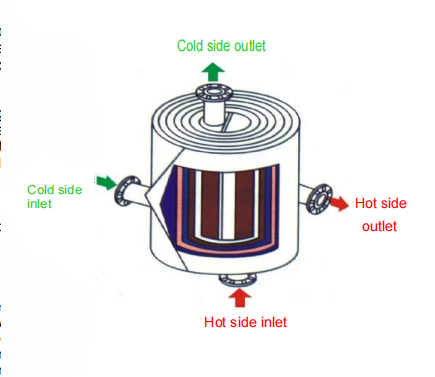

Spiral Heat Exchanger, also Spiral Plate Exchanger or Spiral Exchanger, is composed of two rolled steel plates which form two uniform spiral channels where two heat transfer media can realize a full counter-current flow and thus substantially enhance heat exchange effect. The connecting tube on the crust is of shear structure and featured by small local resistance.

As the curvature of spiral channels is uniform, there is no great steering of fluid flow in the equipment. The total resistance is small. So it is possible to make the equipment possess fairly high heat transfer capacity through raising the designed flow rate. Appropriate technical calculation should be conducted at the time of equipment selection to make the media in channels reach turbulence state. (The flow rate of fluid is greater than 1m/s and that of gas is greater than 10m/s in general.)

High heat transfer efficiency

The heat transfer efficiency of Spiral Plate Exchanger is 1-3 times as much as that of Shell And Tube Heat Exchanger . The maximum heat transfer coefficient is up to 3,300W/(㎡k).

Effective recovery of low-temperature heat energy

Two heat transfer media in the equipment can realize heat transfer through a full countercurrent flow, being applicable to heat transfer with small temperature difference, recovery of waste heat, and full application of low-temperature heat energy.

Strong operating reliability

The two non-removable channels are welded for sealing, which can ensure that the two media are not mixed together.

Small resistance

Spiral Exchanger can process large-volume steam or gas with fairly small pressure loss. It has a self-cleansing ability, for the media flow spirally and results in remote possibility for dirt deposition. It can be easily cleaned with steam or lye and allows for installation of cleaning device. As the medium flows in a single channel, and the allowed flow rate is higher than that of other kinds of heat exchangers.

Electrolyte heating, Concentrated lye cooling, Quenching oil cooling, Fuming Sulfuric Acid cooling, Fatty acid cooling, Steam condensation and more.

Nominal heat exchange area

Distance between channels

Calculation heat exchange area

Nominal diameter of pipe

1. Why Spiral Heat Exchanger but not Plate And Frame Heat Exchanger or Brazed plate heat exchanger?

The spiral shape reduces friction resistance, and allows the fluids to go smoothly. Therefore, it performs under fast flow rate so as to deal with fluid with large quantity.

2. How many types Spiral Plate Exchangers are there?

We have Spiral Exchanger Type I, II, and III. Main difference among the three is that whether the machine is removable.

Product Categories : Spiral Plate Heat Exchanger