Guangdong Jiema Energy Saving Technology Co.,Ltd

Sulfuric Acid Heat Exchanger,Compact Size Heat Exchanger,Heat Transfer Equipement

Guangdong Jiema Energy Saving Technology Co.,Ltd

Sulfuric Acid Heat Exchanger,Compact Size Heat Exchanger,Heat Transfer Equipement

| Unit Price: | USD 500 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

Brand: JIEMA

100L: carbon steel

Stainless Steel: flange

Packaging: wooden box

Productivity: 10000 set s

Transportation: Air,Land,Ocean

Place of Origin: Guangzhou

Supply Ability: 1000 sets/month

Certificate: CE ISO

Port: Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CIF

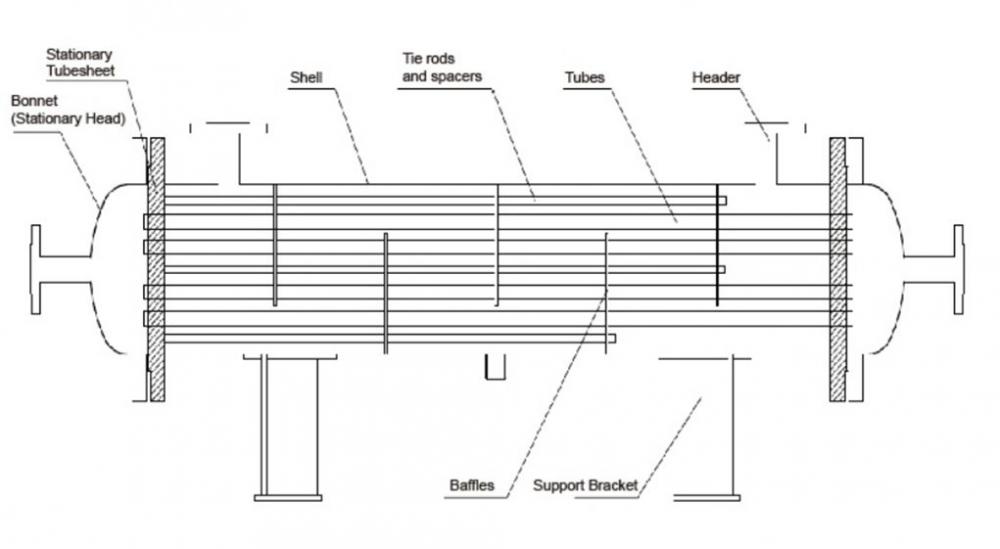

Fixed Shell and Tube HE for chemical Industry

Introduction

Fixed tube Plate Heat Exchanger at both ends of the tube plate and shell made of one, when the temperature difference between the two fluids is large, the appropriate location in the shell welded on a compensation ring (or expansion joint). When the shell and tube bundle thermal expansion is different at the same time, the compensation ring occurs slowly elastic deformation to compensate for the thermal expansion caused by the temperature difference stress.

What is the Structure of Fixed Tube Heat Exchanger?

The tube bundle connected to the tube plate, which are welded to the ends of the shell, and in its connection with the top cover, the top cover and shell is equipped with fluid inlet and outlet receiver.

Usually a series of baffles perpendicular to the tube bundle are installed outside the tube. At the same time both the tube and the tube plate are connected to the shell rigidly, while inside and outside the tube are two different temperatures of the fluid.

Therefore, when the tube wall and shell wall temperature difference is large, due to the difference in thermal expansion between the two, resulting in a large temperature difference stress, so that the tube twist and bend or make the tube loose from the tube plate, or even destroy the heat exchanger.

In order to overcome the temperature difference stress must have temperature compensation device, generally in the tube wall and shell wall temperature difference of more than 50C, for safety, the Shell And Tube Heat Exchanger should have a temperature compensation device. General shell pressure of more than 0.6Mpa due to the compensation ring is too thick, difficult to expand, lose the role of temperature compensation, should consider other structures.

Product Categories : Shell And Tube Heat Exchanger > Fixed Tube Heat Exchanger