Guangdong Jiema Energy Saving Technology Co.,Ltd

Tubular Exchanger,Shell and Tube Boiler,Tema Heat Exchanger

Guangdong Jiema Energy Saving Technology Co.,Ltd

Tubular Exchanger,Shell and Tube Boiler,Tema Heat Exchanger

| Unit Price: | USD 300 / Piece/Pieces |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,Express Delivery,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Piece/Pieces |

Brand: Jiema

Usage: Cooling, Heating

Material: Carbon steel, Stainless steel

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou, China

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: T/T,L/C

Incoterm: FOB,Express Delivery,CFR,CIF,EXW,DDU

TEMA, acronym for Tubular Exchangers Manufacturers Association, infuses standardized requirements with the manufacture of Shell And Tube Heat Exchanger and these specific demands are well accepted among the industry. Jiema Tema Heat Exchanger for Sulfuric Acid Heating is among the various successful Shell And Tube Boilers that meet the standards.

Two fluids, of different starting temperatures, flow through our Tubular Exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes but inside the shell (the shell side). Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. The fluids of our Shell And Tube Boiler can be either liquids or gases.

In order to transfer heat efficiently, a large heat transfer area should be used, leading to the use of many tubes. In this way, waste heat can be put into reuse. This is an efficient way to conserve energy.

| Simple structure, easy manufacturing | GB150~2011,GB/T151-2014,Manufacture License of Special Equipment P.R.C |

| Large processing quantity | (1-2,000m3/h) |

| Stable and reliable operating state | Strong adaptability (applicable to almost all industries) |

| Adaptability to high temperature and pressure | (≤800°C; ≤6.0Mpa) |

| Flexible heat transfer area | (1m2~500m2) |

| Tube material | CS,SS,Copper Tube,Ti,Hastelloy C and other materials |

| Shell material | CS,SS,Ti ,SMO254 and other materials |

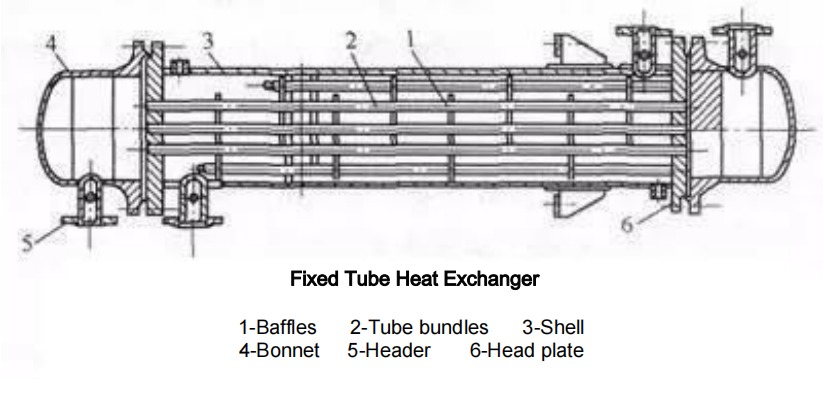

Our Tema Heat Exchanger for Sulfuric Acid Heating is composed of shell, tube bundles, bonnet, head plate, baffles, headers and others.

About Us

About Us

Guangdong Jiema Energy Saving Technology Co., Ltd. (hereinafter referred as Jiema) used to be called Guangzhou Jiema Heat Exchanger Co.,Ltd. It was established in 2005, a reliable enterprise who integrates research, development, design, manufacturing, sales and after-service. Our mission statement is to be a trustworthy partner!

1. Will you conduct pressure/temperature tests for the Tubular Exchanger?

Yes, we will. Among various tests, we do our utmost in order to proceed a

satisfied cooperation.

2. What is Tema Heat Exchanger for Sulfuric Acid Heating?

Tema Heat Exchanger for Sulfuric Acid Heating belongs to the category of

Fixed Tube Heat Exchanger, and is one of the simplest in structure with

relatively low cost. However, improving its efficiency and temperature

difference is still under our lists of priority.

Product Categories : Shell And Tube Heat Exchanger > Fixed Tube Heat Exchanger